Automatic Lubrication System

We offer fully automatic lubrication systems for many different industries. These are dependable and durable systems designed for industrial equipment.

We tailor our solutions to fit the needs of your equipment, no matter what type it may be.

From machine implementation to commissioning and operation, our automatic lubrication system focusses on the continual improvement of machinery automation.

Our expert team combines years of experience and advanced technology in order to provide you with comprehensive solutions that can effectively address your specific needs.

What is an Automatic Lubrication System (ALS)?

An Automatic Lubrication System (ALS), also known as a Centralized Lubrication System (CLS), is a system that continuously delivers controlled amounts of lubricant to multiple locations on a machine while it is in operation.

An Automatic Lubrication System is essential for on road vehicles and off road equipment because it enables them to run on any environment with minimal issues, enhances the uptime, low maintenance budgets, improved performance and productivity.

An Automatic Lubrication System is essential for on road vehicles and off road equipment because it enables them to run on any environment with minimal issues, enhances the uptime, low maintenance budgets, improved performance and productivity.

An automatic lubrication system is critical to the efficiency and longevity of any rotating equipment. Optimal automatic lubrication uses only needed lubricant that reach critical bearings, pivots and joints in small controlled lubricant amounts as needed in the right frequency

The auto lube system forms a thin layer between moving machine parts to avoid these parts scraping against each other. The system works in such a manner that there is no direct metal-to-metal contact of the components. Therefore, protecting them against wear and tear.

The auto lubrication system delivers precise and adequate amounts of lubricant at frequent intervals to every lube point—even if they’re hard to reach. This reduces friction, allowing the machine parts and components to smoothly slide past each other.

How does automatic lubricating system work?

What are the benefits of automatic lubrication system?

If you are looking to extend the life and productivity of your equipment, then the most important step to get is our accurate and reliable Automatic Lubrication System that doesn’t under or over lubricate.

Here is a list of benefits of the auto lube system

- Reduced downtimes, increased machine life and productivity due to efficient lubrication

- More efficient and controlled use of lubricants

- Energy efficiency is achieved from an optimal lubricated machine.

- Low operating budgets for operating repair labor and components

- Hard to reach Lubricant points are easily lubricated while the equipment is moving. It will be unsafe for your technicians to manually lubricate while the equipment is moving therefore you will not achieve optimal lubrication.

What are the components of Automatic Lubrication System?

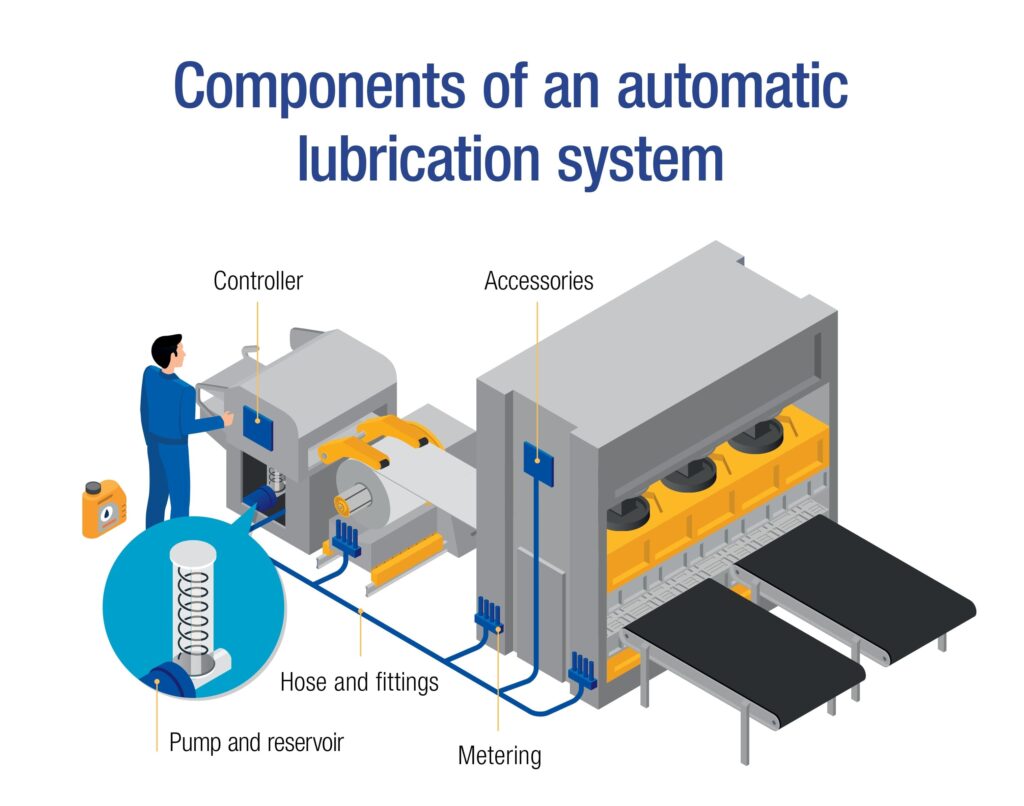

A pump with a reservoir, a controller, metering devices, hose and fittings, and accessories comprise an automatic lubrication system. We have two configurations- Single Line Parallel Automatic Lubrication System and Series Progressive Automatic Lubrication System.

Off road equipment like heavy machinery continuously runs when you install our auto lubrication system as opposed to lubricating the machine manually when it is not running. You can finish your projects faster because your equipment is frequently lubricated efficiently as need arises while moving.

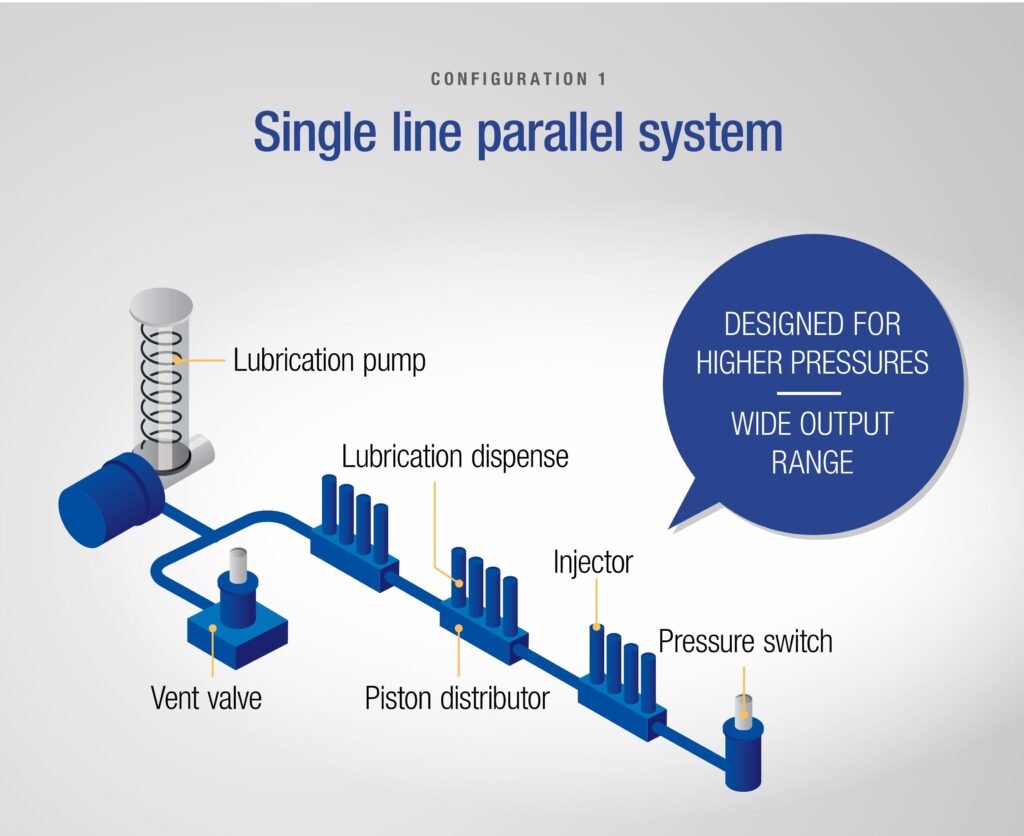

Single Line Parallel Automatic Lubrication System

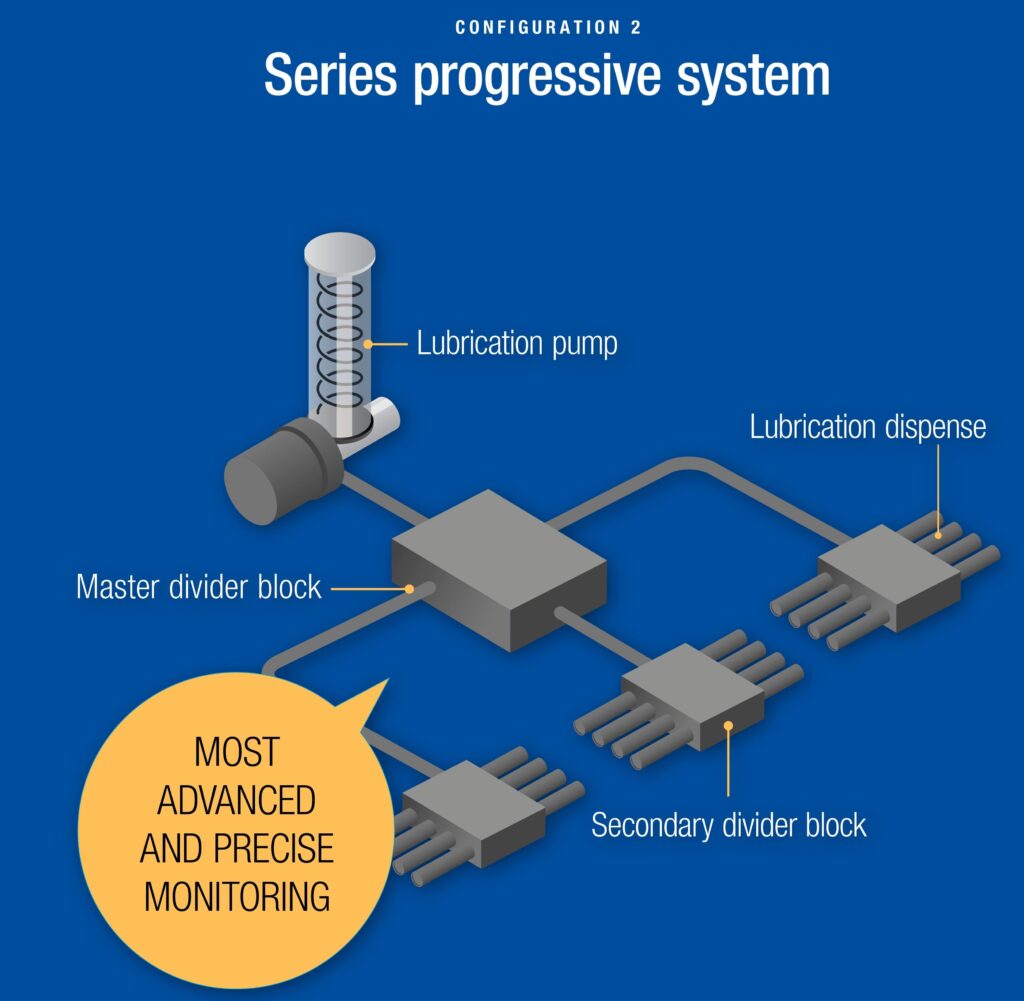

Series Progressive Automatic Lubrication System