Types of Lubrication Systems

Simply put Lubrication systems Reduce Friction, Seal out contamination, Absorb Shock and reduce corrosion among other benefits.

They are mostly beneficial to forward looking equipment manufacturers, operators and managers who value optimal productivity and uptime of machines or equipment.

Our automatic lubrication system is meticulously designed to make your machinery run smoother, faster, and more efficiently.

Manual Lubrication System

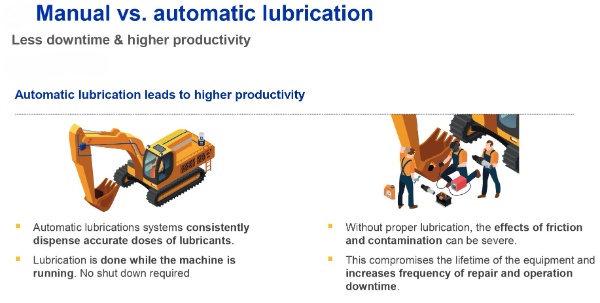

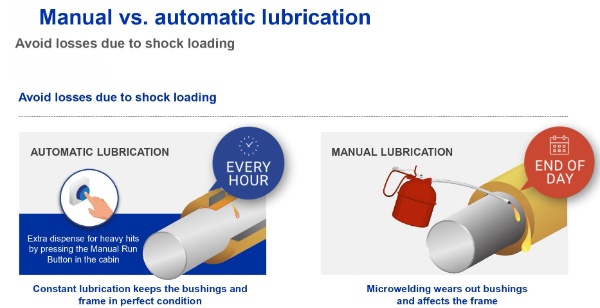

Manual Lubrication system equipment Lubricates manually. Proper lubrication is critical for Heavy duty machinery and equipment.

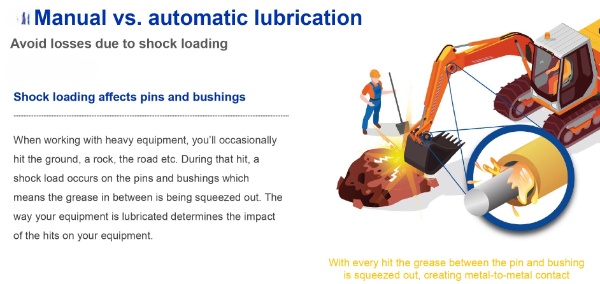

The major pitfall manual lubrication is contamination due to improper lubrication. Dirt can enter the system easily and open lubes may not get adequate grease. On the other hand the excess dirty grease can act as an abrasive which can cause premature failure of bushing and bearing.

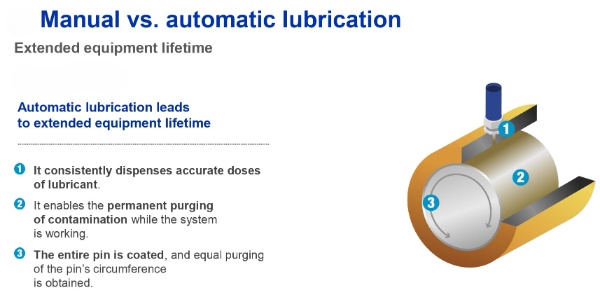

Using automatic lubrication, grease is pumped through a filter before entering the reservoir, which limits the penetration of contaminants into these lube points.

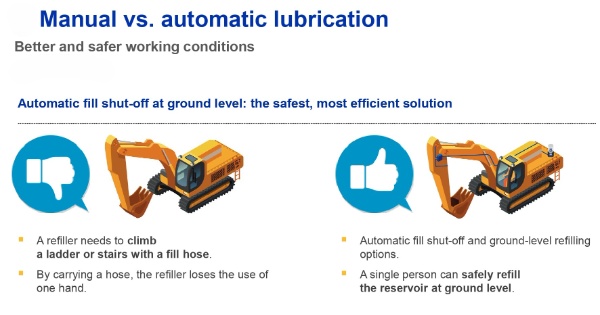

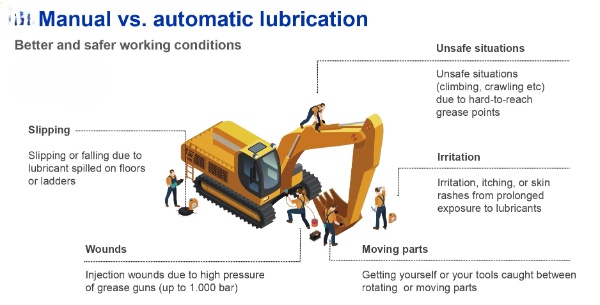

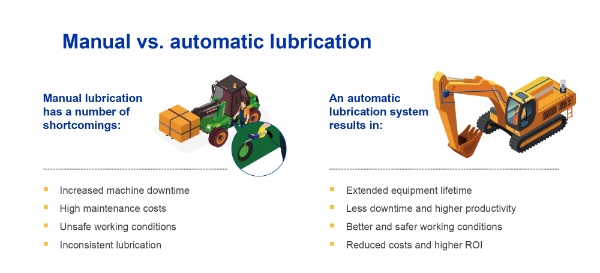

Here are some of the disadvantages of Manual lubrication

- Increased Component wear

- Bearing seal damage

- Product or equipment spoilage

- Dangerous to lubricate while running

- Higher energy usage

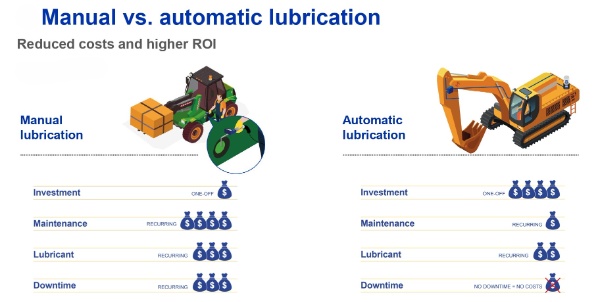

- Increased operating and maintenance costs

- Time Consuming

Automatic Lubrication System

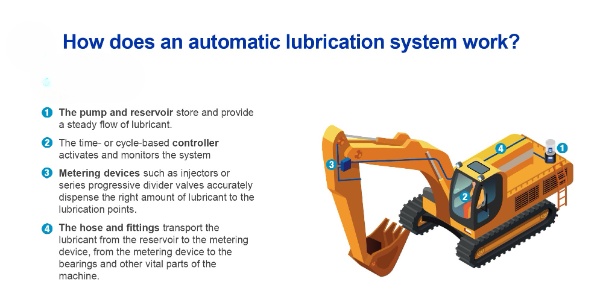

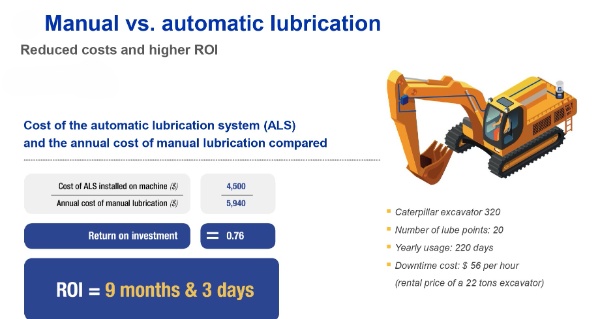

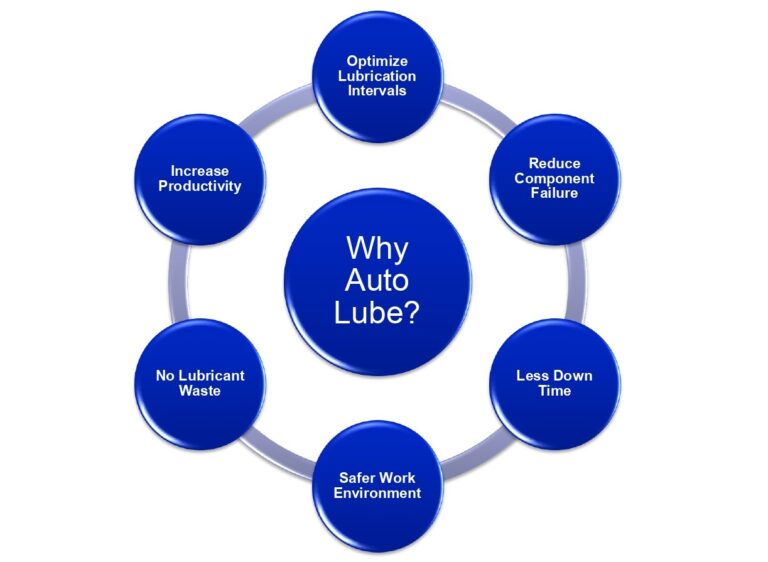

Automatic lubrication system has been specifically designed to increase machine uptime by forming a thin layer between moving machine parts to avoid these parts scraping against each other. It also provides small amounts of lubricant at more frequent intervals, reducing the consumption of lubricant. By reducing wear on the equipment, you will save on spare parts.

Our Automatic Lubrication Systems help you protect your investment. With a lubrication system that automatically

delivers precise amounts of lubricant.

Proper equipment maintenance extends machine life span, improves performance and productivity, and lowers repair costs.

Automatic Lubrication system is the most important preventive maintenance step in extending the life and productivity of any fleet or Heavy duty machinery and equipment.

Automatic lubrication systems come in three different types; Single-Line Parallel, Series Progressive, Dual Line and Multi-Line.

Why is an Automatic lubrication system important?

Automatic lubrication system is a safer method of supplying the required lubrication needed by the equipment. It also offers numerous benefits such as

- Extended equipment life

- Reduced consumption of lubricant

- Reduced maintenance costs

- Reduced machine downtime

- Safer and healthier working conditions

- Environmental improvements

- Suitable for any application

Automatic Lubrication system applications

- On/Off-road machines

- Construction, agriculture and forestry machines

- Machine tools

- Railroad applications

- Steel industry

- Automation

- Mining and cement industry

- Food and beverage

- And more